It has taken a long time, a very long and maddening time, to get to this point, but I’m very pleased to say that we are mostly operational at the bindery. The new glue is working in the glue machine, the casemaker fixes are working properly, and our massive foil stamper has been fine-tuned to deliver the desired results. The “mostly” caveat is due to the fact that we have not yet had the opportunity to test the hub tools yet, although we anticipate doing so in April.

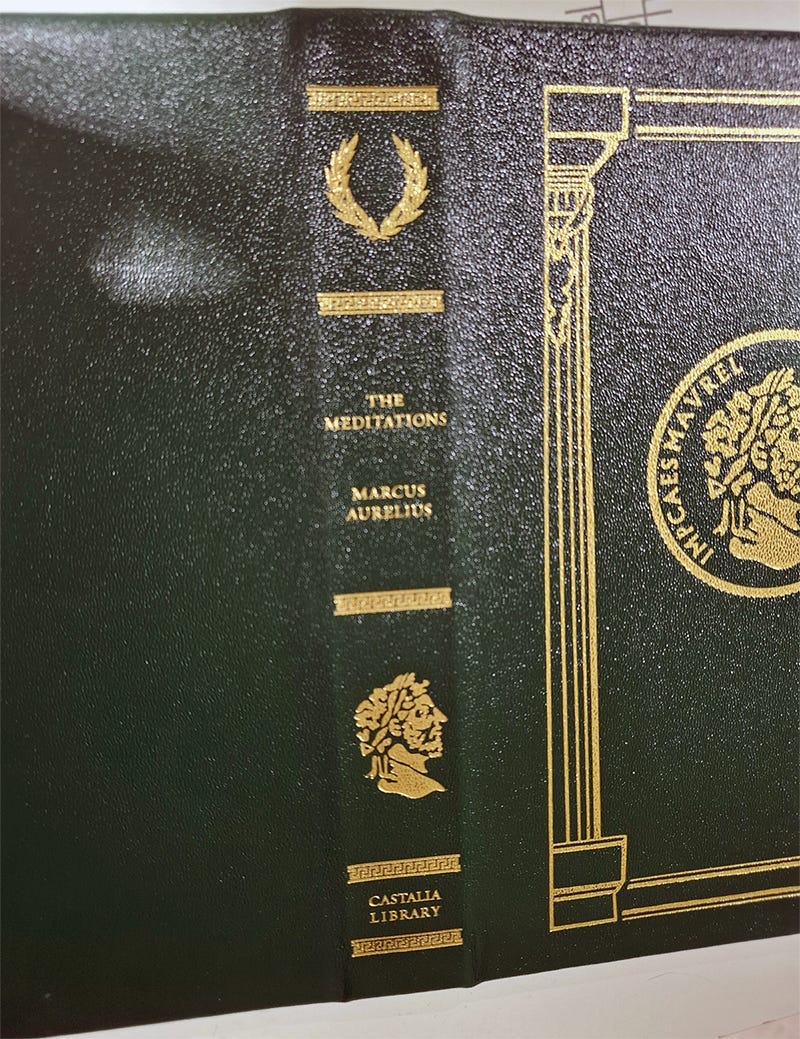

Below is an example of what we have been methodically working toward for the last three years. It is a fully manufactured case, made with the leather that is utilized on all our Library books, correctly stamped to the accurate levels of depth and detail without any pinholing, flaking, or other quality-related problems.

The clean and articulated lines of even the horizontal Roman pattern on the bottom, along with the crisp stamping of the lines and lettering is what we require; the slight blurriness of the stamping on the title and name are an artifact of the lighting, they are not due to the stamping itself.

Now we just are just awaiting the arrival of the book blocks and leather for the two Cambridge Byzantium books, and we’ll get underway.

Beautiful. I currently have a gig which includes, in part, an image for a book cover which will be printed in foil. Seeing the process here has given a deeper appreciation for the design process and the challenge of working within the constraints of the medium. It's also provided a deeper appreciation for the raw technical skill that went into the book-binding process in the past.

Thanks for the update. Wow, that looks absolutely stellar. Great cover!! Good things come to those who wait.